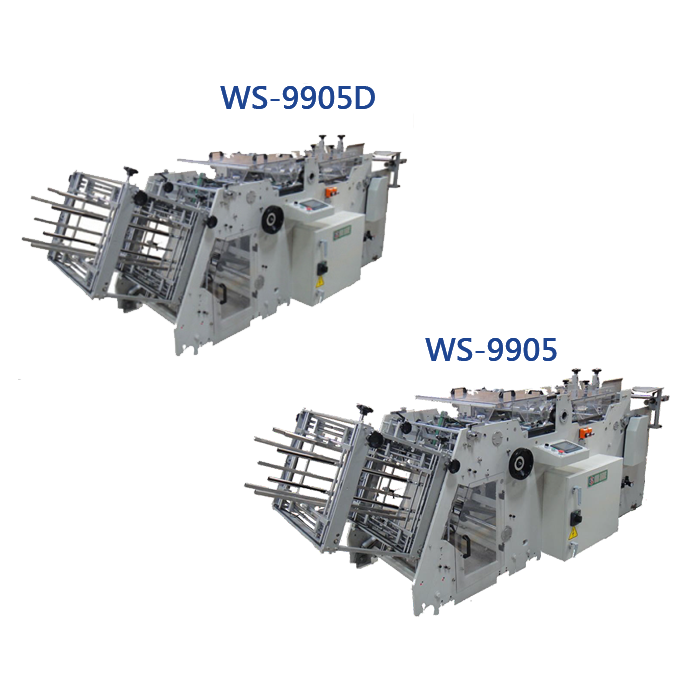

WS-9905S+2C 2 Compartment Carton Erecting and Gluing Machine

Product Introduction

Specification

| Model | Dimension | ||||

| L | W | H | A1 | A2 | |

| WS-9905 | 100~450 | 100~580 | 15~200 | 5~40 | 5~40 |

|---|---|---|---|---|---|

| No. | WS-9905 | WS-9905D | |

| Description | |||

| Production Speed (pcs/min) | Servo : 80~180 | Crank : 80~120 | Servo : 160~360 |

|---|---|---|---|

| Paper Material | |||

| Sealing Method | Glue Sealing | Glue Sealing | |

| Electrical Requirement | Approx. 3 kw | Approx. 3.5 kw | Approx. 3.5 kw |

| Compressed Air | Approx. 100 ℓ/min | Approx. 200 ℓ/min | Approx. 200 ℓ/min |

| Machine Dimension (LxWxH cm) | 370x138x150 | 370x160x150 | 370x160x150 |

| Machine Weight (NW kgs) | 2000 | 2200 | 2200 |

| Mold | 1 | 1 | |

| Material | 200~600g/m2 cardboard or corrugared board E/F/N flute |

200~600g/m2 cardboard or corrugared board E/F/N flute |

|

| Paper Thickness | 0.36~1.5mm | 0.36~1.5mm | |

* Customized design in welcome.

* We reserve the right to alter specifications without prior notice.

Video

WS-9905-Carton erecting machine-Paper

Clamshell box, gluing machine, high speed,

mold changeable, power save.

from Win Shine Machinery from Taiwan on Vimeo.

Application

High-Speed 2-Compartment Carton Erecting and Gluing Machine

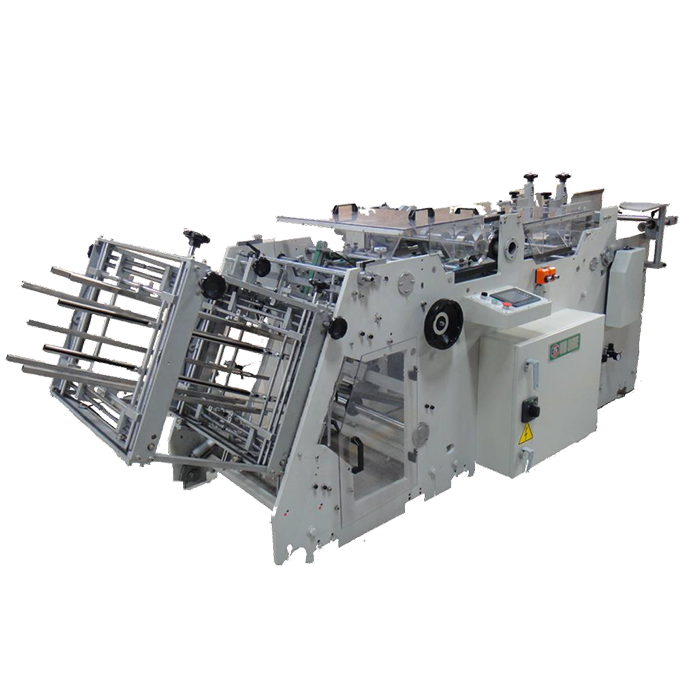

The WS-9905S+2C represents advanced automation in 2-compartment carton assembly, combining high-speed servo control with precision glue sealing technology for industrial packaging operations. This versatile carton erecting machine supports production speeds from 80 to 180 pieces per minute on servo models, delivering consistent quality for food packaging, e-commerce fulfillment, logistics operations, and consumer goods manufacturing.

Servo-Driven Production Performance

The WS-9905 servo system achieves production speeds ranging 80-180 pieces per minute, while the crank-driven variant operates at 80-120 pcs/min, offering flexibility for operations with different throughput requirements. The dual-mold WS-9905D configuration doubles capacity to 160-360 pcs/min, supporting large-scale packaging facilities requiring maximum output efficiency. Servo technology provides superior motion control, reducing mechanical wear while maintaining precise carton formation across extended production runs.

Comprehensive Carton Dimension Range

The WS-9905S+2C accommodates extensive dimensional flexibility with length ranges from 100-450mm, widths from 100-580mm, and heights from 15-200mm. Flap dimensions A1 and A2 support configurations from 5-40mm, enabling diverse 2-compartment box designs for portion-control packaging, multi-product shipping, and sectioned display cartons. This broad forming range allows manufacturers to produce standardized packaging and custom configurations on the same equipment without extensive retooling.

Advanced Material Compatibility

Supporting cardboard and corrugated board materials ranging 200-600 g/m² with E, F, and N flute specifications, the WS-9905S+2C processes paper thicknesses from 0.36-1.5mm. This material versatility accommodates lightweight consumer packaging, medium-weight food service containers, and heavy-duty shipping cartons. Corrugated flute options provide crush resistance and cushioning properties essential for product protection during distribution.

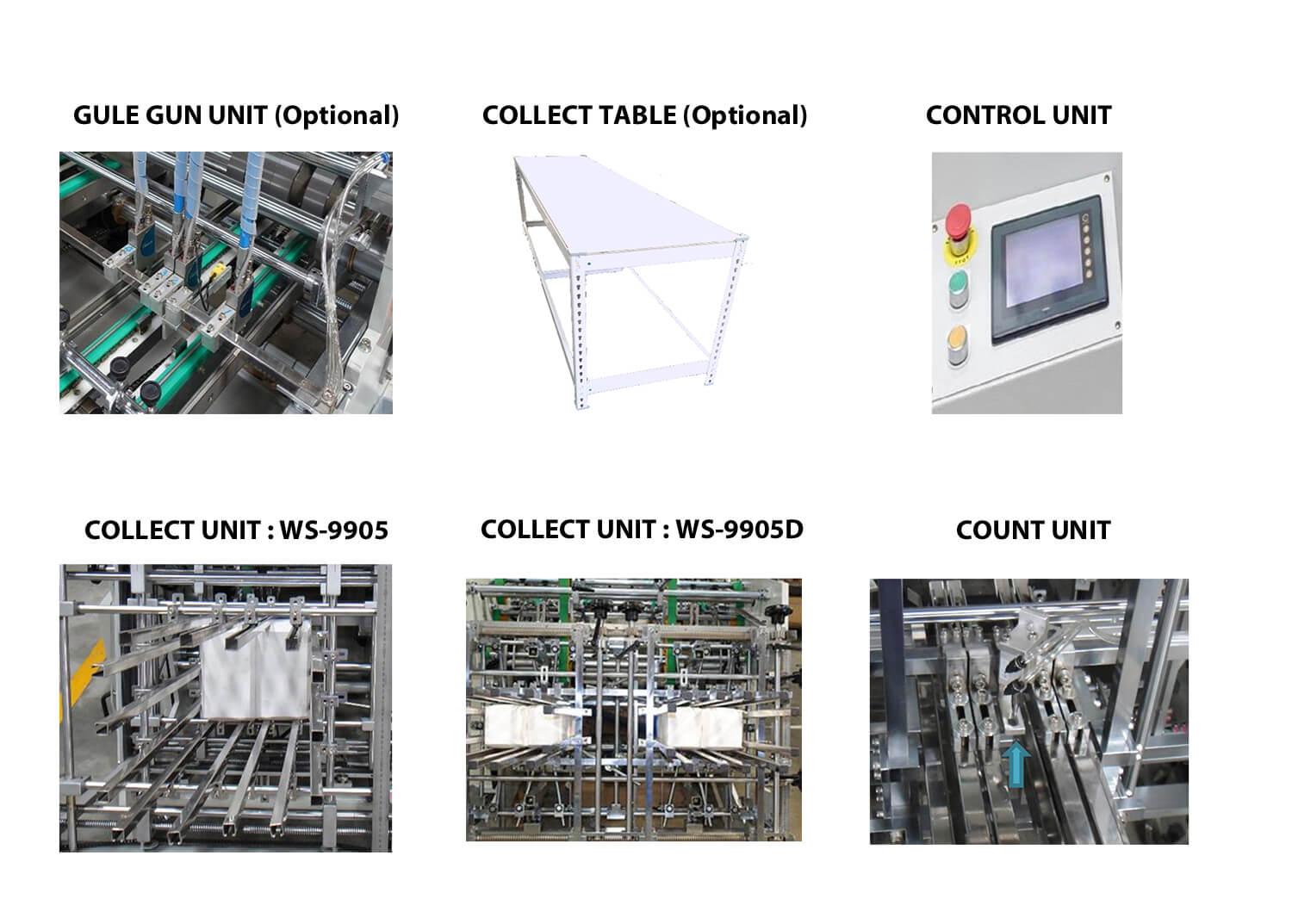

Precision Glue Sealing Technology

The glue sealing method ensures reliable carton assembly with clean, strong bonds that withstand handling and transportation stresses. Automated adhesive application delivers consistent coverage while minimizing glue consumption and reducing material costs. The sealing system accommodates various adhesive formulations including hot-melt, cold-glue, and eco-friendly water-based options to meet different packaging requirements and sustainability objectives.

Energy-Efficient Compact Design

With approximately 3KW electrical consumption for single-mold configurations and 3.5KW for dual-mold systems, the WS-9905S+2C maintains energy-efficient operation while delivering industrial production capacity. Compressed air requirements range from 100 ℓ/min for the WS-9905 to 200 ℓ/min for WS-9905D models, optimizing utility consumption. The compact 370×138×150cm footprint (WS-9905) or 370×160×150cm (WS-9905D) conserves factory floor space while supporting integrated production workflows.

Changeable Mold System

The quick-change mold design enables rapid production switchovers between different carton dimensions and compartment configurations, minimizing downtime during format changes. Single-mold systems support focused production runs, while manufacturers requiring format flexibility can specify custom mold sets for diverse packaging portfolios. This modular approach maximizes equipment utilization across varying order volumes and product lines.

Industry Applications

Food and Beverage Packaging:

The 2-compartment design serves food service operations requiring separated storage for main dishes and sides, sauce compartments, or ingredient separation in meal kits and prepared food packaging. The compartmentalized structure maintains product integrity and presentation quality during refrigerated distribution and retail display.

E-Commerce and Retail:

Online retailers and multichannel merchants utilize 2-compartment cartons for bundled product shipments, promotional packaging, and subscription box fulfillment where product separation prevents damage and enhances unboxing experience. The consistent carton quality supports automated filling systems and reduces packaging waste.

Consumer Electronics and Hardware:

Electronics manufacturers employ compartment cartons to separate devices from accessories, protective materials, and documentation, ensuring organized presentation and component protection. The structural rigidity of corrugated configurations provides crush resistance for fragile items.

Pharmaceutical and Healthcare:

Pharmaceutical packaging applications leverage compartment separation for multi-product kits, medical device packaging, and over-the-counter medication bundles requiring distinct product segregation. The precise forming ensures compliance with pharmaceutical packaging standards.

Automation Benefits

Carton erecting machines eliminate manual assembly labor while increasing throughput, reducing packaging costs per unit. Automated operation ensures dimensional consistency critical for downstream filling, sealing, and palletizing equipment integration. The reduction in repetitive manual tasks improves workplace ergonomics and reallocates labor to higher-value production activities.

Customization and Engineering Services

Win Shine (允享機械) provides comprehensive customization support for specialized packaging requirements beyond standard configurations. Engineering teams collaborate on custom mold development for unique compartment layouts, specialized dimensional requirements, and integration with existing packaging lines. Technical services include production testing, operator training, preventive maintenance protocols, and spare parts supply to ensure optimal long-term performance.

Taiwan Manufacturing Excellence

Backed by Taiwan's precision engineering reputation and Win Shine's decades of paper forming equipment expertise, the WS-9905S+2C delivers reliable industrial performance with proven component durability. Quality manufacturing standards ensure consistent carton formation accuracy, glue sealing integrity, and mechanical reliability across extended operational lifecycles. The robust construction minimizes maintenance requirements while supporting 24/7 production schedules.

Sustainable Packaging Solutions

Carton erecting equipment supports sustainable packaging initiatives by processing recyclable cardboard and corrugated materials that decompose naturally without environmental harm. Efficient glue application systems minimize adhesive consumption, while precision forming reduces material waste. This eco-friendly production aligns with corporate sustainability commitments and consumer preferences for responsible packaging.

Request Equipment Information

Contact Win Shine Machinery for detailed specifications, production samples, custom mold consultations, and packaging line integration assessments. Engineering teams provide carton design optimization, production workflow analysis, and ROI calculations to support equipment investment decisions. Request equipment demonstrations and facility tours to evaluate the WS-9905S+2C for specific production requirements.