WS-9905D Dual-Mold Automatic Food Container Making Machine

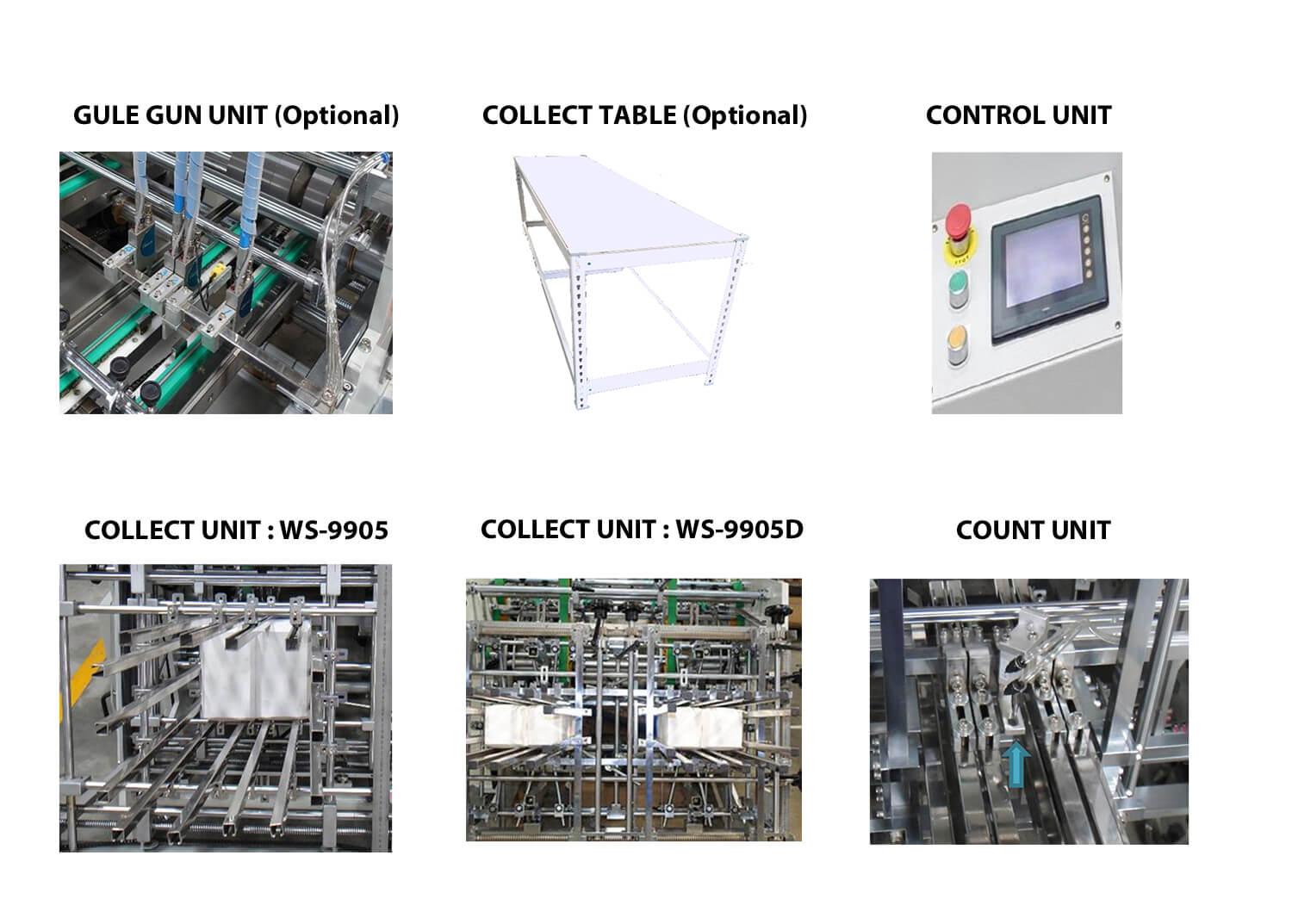

Product Introduction

Description

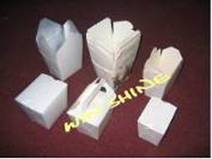

A carton box erecting forming machine is widely used in the food packaging industry to produce various types of food boxes, including:

- Burger Boxes – Used for packaging burgers and meals, ensuring freshness during transport.

- French Fries Boxes – For packaging fries and fried foods with oil and moisture resistance.

- Bento Boxes – Multi-compartment boxes for lunch sets or takeout meals, customizable for specific needs.

- Soup Boxes – Leak-proof containers for hot soups and liquids, maintaining food temperature.

- Salad Boxes – For packaging salads or cold meals with transparent lids and foldable bases.

- Pastry Boxes – For cakes and pastries, combining aesthetics and functionality.

- Pizza Boxes – Oil-resistant, larger boxes specifically for pizza packaging.

- Chicken Wing Boxes – Designed for fried chicken, with oil and moisture resistance.

The carton box erecting forming machine improves production efficiency and meets the diverse needs of food box manufacturing, enhancing packaging quality in the food service industry.

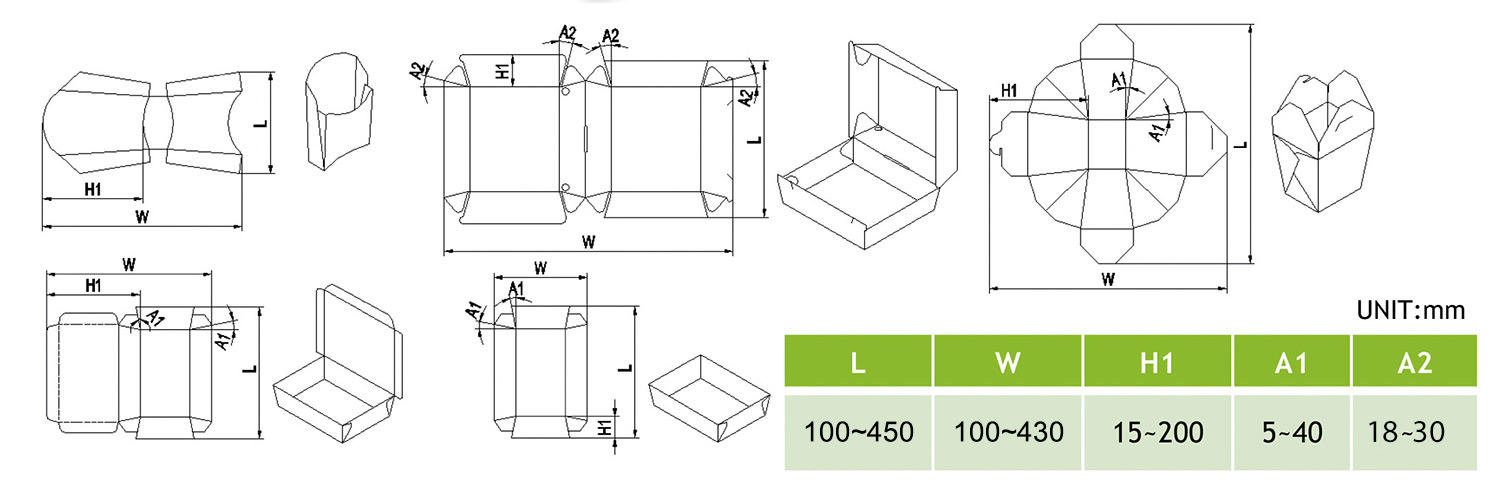

Specification

| Model | Dimension | ||||

| L | W | H | A1 | A2 | |

| WS-9905D | 100~450 | 100~430 | 15~200 | 5~40 | 18~30 |

|---|---|---|---|---|---|

| No. | WS-9905D |

| Description | |

| Production Speed (pcs/min) | Servo : 160~360 |

|---|---|

| Paper Material | 200~600g/m2 cardboard or corrugared board E/F/N flute |

| Sealing Method | Glue Sealing |

| Electrical Requirement | Approx. 7.5 kw |

| Compressed Air | Approx. 200 ℓ/min |

| Machine Dimension (LxWxH cm) | 321x200x150 |

| Machine Weight (NW kgs) | 2200 |

| Paper Thickness | 0.36~1.5mm |

* Customized design in welcome.

* We reserve the right to alter specifications without prior notice.

Video

Application