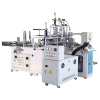

WS-8809ER 3-5 Multi-Compartment Lunch Box Forming Machine

Product Introduction

Win Shine made the first four compartment lunch box machine since 2000, Invented the most paper-saving multi-compartment lunch box design. At the machine, this WS-8809ER is the best to buy and High investment return rate and minimum floor space. We also have bigger size boxes type at 3~5 compartment box forming machines.

Specification

| Model | Dimension | ||

| L | W | H | |

| WS-8809ER | 145-175 | 100-145 | 32-42 |

| 145-180 | 145-160 | 32-42 | |

| No. | WS-8809ER | |||

| Description | ||||

| Sealing Method | Heater + Hi-frequency | |||

|---|---|---|---|---|

| Machine Dimension (LxWxH cm) | 360 x 150 x 225cm | |||

| Machine Weight (kgs) | 1200 | |||

| Max. Production Speed (pec/min) | 22 | |||

| Forming Model |  |

|

|

|

| Mold | 1 Mold | |||

| Paper Material | Single or Double PE coated paper ISG-320g/m2~350g/m2 | |||

| Paper Thickness | Main Box 0.46mm~0.50mm Small divisions 0.38mm |

|||

| Electrical Requirement M/C + Hi-friquency | 8.5Kw/hr. 50A+30A |

|||

| Air Requirement | 6kg/cm2 x 132 Liter/min | |||

* Customized design in welcome.

* We reserve the right to alter specifications without prior notice.

Video

Industry-First Four-Compartment Innovation Since 2000

The WS-8809ER represents groundbreaking engineering achievement as Win Shine's first four-compartment lunch box machine launched in 2000, establishing industry precedent for multi-section food packaging technology. This pioneering system introduced the world's most paper-saving multi-compartment lunch box design, revolutionizing material efficiency standards across commercial food service operations. With over 25 years of proven field performance, the WS-8809ER continues delivering exceptional return on investment while maintaining minimal factory floor space requirements.

Most Paper-Saving Multi-Compartment Design

The WS-8809ER's patented engineering achieves unprecedented material efficiency through innovative compartment layout geometry that minimizes paper consumption per unit. Traditional multi-compartment designs require overlapping material layers and reinforced seams that increase substrate usage by 15-30%. Win Shine's optimized configuration eliminates redundant material while maintaining structural integrity, reducing paper costs by approximately 20-25% compared to conventional four-compartment systems.

This paper-saving innovation delivers substantial economic benefits for high-volume operations. Annual material cost reductions for facilities producing 1 million lunch boxes can exceed $50,000-75,000, significantly improving profit margins and competitive positioning. The environmental impact is equally compelling—reduced paper consumption decreases forestry demand and waste generation, supporting corporate sustainability commitments.

Highest Investment Return Rate

The WS-8809ER achieves industry-leading ROI through the convergence of material efficiency, production capacity, and operational reliability. The paper-saving design generates immediate cost advantages while 22 pieces per minute capacity supports daily volumes exceeding 9,000 lunch boxes across standard shifts. Combined with minimal downtime and reduced maintenance requirements, operators typically recover equipment investment within 18-24 months compared to 36-48 month payback periods for conventional systems.

The compact 360×150×225cm footprint maximizes facility utilization, enabling profitable production in space-constrained urban kitchens and multi-purpose facilities where floor space commands premium costs. At 1,200kg machine weight, the WS-8809ER offers installation flexibility without requiring structural reinforcement typical of heavier industrial equipment.

Optimized Production Performance

Achieving 22 pieces per minute maximum speed, the WS-8809ER balances throughput with precision forming quality essential for multi-compartment configurations. This production rate supports medium-to-large-scale catering operations, institutional food services, and commercial meal preparation facilities managing daily order volumes of 5,000-10,000 portioned meals. The consistent cycle time enables predictable production scheduling coordination between food preparation and packaging availability.

The reliable mechanical operation maintains steady output throughout extended production runs, minimizing downtime and maximizing operational efficiency critical for just-in-time meal service operations. This performance consistency makes the WS-8809ER ideal for operations dependent on uninterrupted packaging supply for daily meal distribution.

Advanced Heater Plus High-Frequency Sealing

The WS-8809ER employs proven heater and high-frequency sealing combination delivering consistent, leak-resistant closures across both single and double PE-coated paper substrates. High-frequency technology operates at 27.12 MHz generating molecular bonding between PE layers, creating airtight seals that maintain food quality during distribution and storage. The integrated heater element ensures uniform temperature across sealing zones, guaranteeing reliable seal formation throughout production cycles.

This dual-sealing approach provides process redundancy enhancing overall seal reliability—if heater performance varies due to environmental factors, the high-frequency component maintains consistent bonding strength. The result is dependable leak resistance critical for reputation-sensitive food service operations serving compartmentalized meals with sauces and liquids.

Versatile Single or Double PE Compatibility

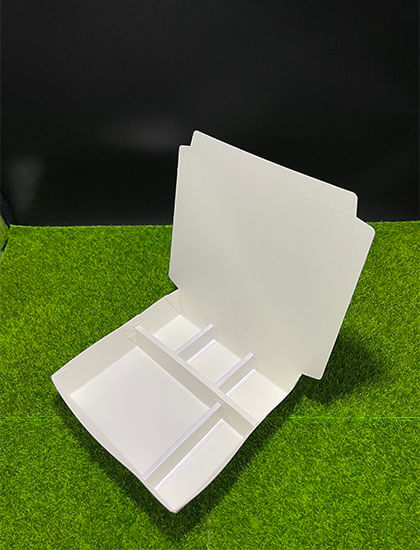

Supporting both single and double PE-coated paper (320-350 g/m²), the WS-8809ER provides operational flexibility unmatched by systems limited to single material types. Single PE-coated paper offers cost-effective solutions for dry food applications and budget-conscious packaging programs. Double PE-coated configurations deliver enhanced moisture and grease barrier properties essential for hot foods, high-liquid-content meals, and premium packaging applications.

Main box construction utilizes 0.46-0.50mm paper thickness for structural rigidity, while compartment dividers employ efficient 0.38mm thickness providing clean separation without excess material consumption. This optimized thickness specification balances strength requirements with the paper-saving design philosophy.

Dual Dimensional Range Flexibility

Configuration One:

Produces boxes measuring 145-175mm length × 100-145mm width × 32-42mm height, suitable for standard portion-controlled meals and compact applications. This dimension range accommodates school lunch programs, children's meals, and portion-restricted institutional dining.

Configuration Two:

Accommodates larger dimensions of 145-180mm length × 145-160mm width × 32-42mm height, supporting generous adult portions and multi-component meal applications. The wider format provides ample space for elaborate multi-course meals popular in commercial catering and premium takeout services.

Both configurations maintain the same paper-saving efficiency and sealing technology, enabling operators to select models matching specific market segment requirements.

3-5 Compartment Versatility

The WS-8809ER accommodates flexible 3-5 compartment configurations supporting diverse meal presentation formats. Three-compartment layouts suit balanced meal presentations with main dish, side, and accompaniment separation. Four-compartment designs—the original 2000 innovation—support multi-course meals with separate sections for proteins, vegetables, starches, and accompaniments. Five-section premium configurations enable comprehensive meal services including appetizers, mains, sides, desserts, and condiments in single integrated packaging.

The paper-saving design maintains material efficiency across all compartment counts, delivering consistent cost advantages regardless of section configuration.

Energy-Efficient Technical Specifications

Operating on 8.5KW/hr electrical consumption (50A + 30A for machine and high-frequency systems), the WS-8809ER maintains energy-efficient performance throughout production cycles. The 6kg/cm² compressed air requirement at just 132 liters per minute represents significant utility savings compared to higher-consumption systems requiring 500-750 L/min. These reduced utility specifications enable straightforward integration into existing facilities without requiring specialized infrastructure upgrades.

Market Applications

Institutional Food Services:

Schools, hospitals, corporate cafeterias, and senior living facilities utilize the WS-8809ER for standardized portion-controlled meal packaging meeting nutritional guidelines and dietary requirements. The paper-saving design reduces operational costs while the 3-5 compartment flexibility accommodates diverse therapeutic diet specifications.

Commercial Catering Operations:

Large-scale catering businesses depend on efficient multi-compartment production for event meals, corporate dining, and special occasion services. The high ROI supports profitable operations in competitive commercial catering markets.

Airline and Railway Catering:

Transportation food services leverage compact multi-compartment boxes for in-flight and on-board meal service. The paper-saving design reduces aircraft weight and transportation costs while the leak-resistant sealing prevents spills during vehicle movement.

Meal Kit and Prepared Food Manufacturers:

Meal kit providers and prepared food companies employ multi-compartment packaging for portion-controlled ingredient separation and multi-component meal assembly. The material efficiency improves packaging costs per unit while supporting sustainable branding initiatives.

Minimal Floor Space Requirements

The WS-8809ER's compact 360×150×225cm footprint delivers best-in-class space efficiency for multi-compartment forming equipment. This minimal floor space requirement enables profitable production in space-constrained urban kitchens, multi-purpose facilities, and operations where real estate costs significantly impact profitability. The compact design also facilitates equipment relocation and production line reconfigurations responding to changing operational needs.

25-Year Evolution and Refinement

Since the groundbreaking 2000 launch, the WS-8809ER has undergone continuous improvement incorporating operator feedback, material advancements, and efficiency optimization. The integration of single/double PE compatibility represents significant engineering adaptation responding to diverse market requirements. This evolutionary approach ensures the pioneering platform remains relevant amid changing market dynamics while preserving the fundamental paper-saving innovation that established its reputation.

Customization and Engineering Support

Win Shine (允享機械) provides comprehensive customization services including custom compartment layouts, specialized dimensional requirements, and brand-specific packaging designs. Engineering teams collaborate on material optimization, sealing parameter adjustments, and production workflow integration maximizing output efficiency. Technical support encompasses operator training, preventive maintenance programs, and spare parts supply ensuring long-term operational reliability.

Taiwan Manufacturing Excellence

Backed by Taiwan's precision engineering reputation and Win Shine's 25+ years of WS-8809ER production expertise, this pioneering system delivers reliable long-term performance with proven component durability. The quarter-century production history demonstrates enduring mechanical design and field-proven performance across diverse operating environments worldwide. Quality manufacturing standards ensure consistent forming accuracy, sealing integrity, and operational longevity throughout extended service lives.

Sustainable Packaging Leadership

The WS-8809ER's paper-saving design positions operators at the forefront of sustainable packaging innovation. Reduced material consumption decreases forestry demand and waste generation while single/double PE compatibility enables strategic substrate selection matching environmental commitments. This sustainability leadership helps food service operations meet regulatory requirements and satisfy consumer preferences for responsible packaging.

Request Equipment Information

Contact Win Shine Machinery for detailed specifications, production samples, paper-saving analysis, and facility integration consultations. Engineering teams provide compartment layout optimization, ROI modeling, and production capacity assessments supporting equipment investment decisions. Request demonstrations and material efficiency testing evaluating the WS-8809ER for specific multi-compartment lunch box manufacturing requirements.