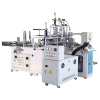

1-Mold 3-5 Compartment Lunch Box Forming Machine

Classic 3-5 Compartment Lunch Box Forming Machine

The WS-8809B represents proven engineering in multi-compartment lunch box manufacturing, delivering reliable 3-5 section production with 17 pieces per minute capacity for established food service operations. This classic model combines time-tested heater plus high-frequency sealing technology with versatile single or double PE-coated paper compatibility, supporting diverse meal packaging requirements across commercial catering, institutional dining, and takeout services.

Enhanced Production Speed

At 17 pieces per minute maximum production speed, the WS-8809B delivers higher throughput compared to entry-level models while maintaining consistent quality output. This production capacity suits medium-scale food service operations requiring daily volumes between 4,000-7,000 lunch boxes across standard eight-hour shifts. The enhanced speed enables efficient order fulfillment for catering businesses, school meal programs, and commercial meal preparation facilities managing regular delivery schedules.

The reliable mechanical operation ensures predictable production planning with minimal downtime, supporting operations that depend on consistent packaging availability for daily meal services.

Single or Double PE Paper Versatility

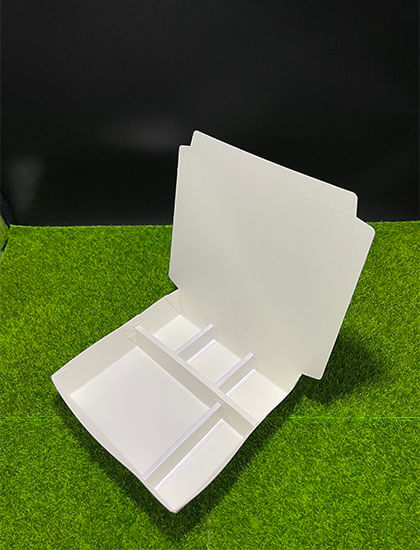

The WS-8809B's compatibility with both single and double PE-coated paper provides operational flexibility unmatched by systems limited to single material types. Single PE-coated paper (320-350 g/m²) offers cost-effective solutions for dry food applications, ambient-temperature meals, and budget-conscious packaging programs. Double PE-coated configurations deliver enhanced moisture and grease barrier properties essential for hot foods, high-liquid-content meals, and premium packaging applications requiring superior leak resistance.

This material versatility enables manufacturers to optimize packaging costs by matching substrate specifications to specific menu items—using economical single PE for dry foods while reserving double PE for moisture-sensitive applications. The dual-material capability maximizes equipment utilization across diverse product portfolios without requiring separate forming systems.

Proven Heater Plus High-Frequency Sealing

The WS-8809B employs established heater and high-frequency sealing combination that delivers consistent, leak-resistant closures across both single and double PE paper substrates. High-frequency technology operates at 27.12 MHz to generate molecular bonding between PE layers, creating airtight seals that maintain food quality during distribution and storage. The integrated heater element ensures uniform temperature across sealing zones, guaranteeing reliable seal formation regardless of production speed variations.

This dual-sealing approach provides process redundancy that enhances overall seal reliability—if heater performance varies due to environmental factors, the high-frequency component maintains consistent bonding strength. The result is dependable leak resistance critical for reputation-sensitive food service operations.

Optimized Dimensional Range

The WS-8809B accommodates two distinct forming ranges to serve different market segments. The first configuration produces boxes from 145-175mm length × 100-145mm width × 32-42mm height, suitable for standard portion-controlled meals and single-serving applications. The second range handles 145-180mm length × 145-160mm width × 32-42mm height dimensions, supporting wider box formats for multi-component meals and generous portion sizes.

Main box construction utilizes 0.46-0.50mm paper thickness for structural rigidity, while compartment dividers employ efficient 0.38mm thickness that provides clean separation without excess material consumption. This optimized thickness specification balances strength requirements with material economy.

Compact Space-Efficient Design

The 360×150×225cm machine footprint delivers compact installation compared to larger dual-mold systems, conserving valuable factory floor space while maintaining industrial production capability. The 1,200kg machine weight provides operational stability during high-frequency sealing cycles while remaining manageable for facility layout modifications and production line reconfigurations. The single-mold design simplifies maintenance access and reduces spare parts inventory requirements compared to multi-mold configurations.

Energy and Utility Requirements

Operating on 8.5KW/hr electrical consumption (50A + 30A for machine and high-frequency systems), the WS-8809B maintains energy-efficient performance throughout production cycles. The 6kg/cm² compressed air requirement at 750 L/min supports pneumatic components for paper feeding, forming operations, and automated stacking functions. These utility specifications enable straightforward integration into existing production facilities without requiring specialized infrastructure upgrades.

Food Service Applications

School Nutrition Programs:

Educational institutions utilize the WS-8809B for standardized lunch box production that meets USDA nutrition guidelines and portion control requirements. The 3-5 compartment configurations accommodate balanced meals with separate sections for proteins, grains, vegetables, fruits, and dairy components.

Corporate Catering Services:

Business catering operations depend on consistent lunch box production for office deliveries, corporate events, and employee dining programs. The 17 pcs/min capacity supports efficient order processing during morning preparation windows for midday meal delivery schedules.

Healthcare Food Service:

Hospital patient dining and healthcare facility meal programs leverage compartmentalized packaging for dietary management, portion control, and allergen separation. The single/double PE material options accommodate different dietary texture requirements and food temperature specifications.

Quick-Service Restaurant Takeout:

Fast-casual restaurants and quick-service establishments use the WS-8809B for consistent takeout packaging that maintains food separation during delivery and carryout services. The reliable sealing prevents sauce leakage and maintains meal presentation quality.

Operational Benefits

Material Cost Optimization:

The single/double PE versatility enables strategic material selection based on menu requirements, reducing packaging costs by 15-25% compared to systems requiring premium substrates for all applications. Operations can reserve expensive double PE for moisture-sensitive items while using economical single PE for appropriate menu components.

Production Predictability:

The classic mechanical design delivers consistent cycle times and minimal speed variations, supporting accurate production scheduling essential for just-in-time meal preparation operations. Predictable output enables tight coordination between food preparation and packaging availability.

Simplified Training:

The straightforward operation and proven technology reduce operator training time compared to complex servo-driven systems, enabling faster workforce onboarding and operational flexibility. Standard mechanical controls provide intuitive adjustment access for basic troubleshooting and routine maintenance.

Single-Mold Efficiency

The 1-mold configuration focuses production on optimized compartment layouts rather than managing multiple simultaneous formats. This specialization enables deeper process optimization, consistent quality control, and simplified mold changeover procedures when switching between 3, 4, or 5 compartment configurations. Single-mold systems also reduce initial equipment investment and ongoing maintenance costs compared to dual-mold alternatives.

Customization and Technical Support

Win Shine (允享機械) provides comprehensive customization services including custom mold development for specialized compartment layouts, unique dimensional requirements, and brand-specific packaging designs. Engineering teams collaborate on material optimization, sealing parameter adjustments, and production workflow integration to maximize output efficiency. Technical support encompasses operator training, preventive maintenance programs, and spare parts supply ensuring long-term operational reliability.

Sustainable Packaging Leadership

Both single and double PE-coated paper materials support environmental sustainability objectives by providing biodegradable alternatives to plastic foam containers. Paper-based substrates decompose naturally while PE coatings can be separated during recycling processes for material recovery. This eco-friendly positioning helps food service operations meet regulatory requirements and satisfy consumer preferences for responsible packaging.

Proven Taiwan Manufacturing

Backed by Taiwan's precision engineering reputation and Win Shine's extensive paper forming equipment expertise, the WS-8809B delivers reliable long-term performance with proven component durability. The classic design represents decades of refinement in compartment lunch box technology, incorporating field-proven solutions that minimize operational disruptions. Quality manufacturing standards ensure consistent forming accuracy, sealing integrity, and mechanical reliability throughout extended service lives.

Request Equipment Information

Contact Win Shine Machinery for detailed specifications, production samples, material compatibility testing, and facility integration consultations. Engineering teams provide compartment layout optimization, single/double PE cost analysis, and production capacity assessments to support equipment selection decisions. Request demonstrations and trial runs to evaluate the WS-8809B Classic for specific food service packaging requirements.