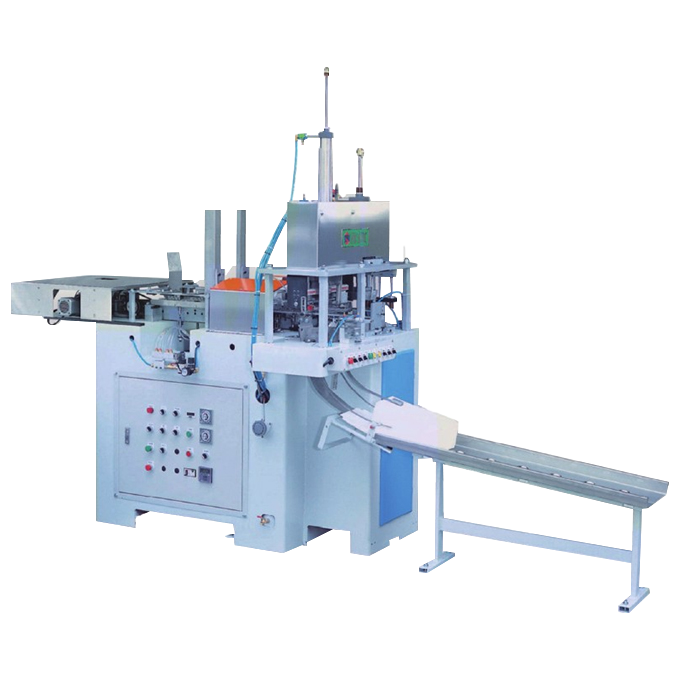

TWO COMPARTMENT LUNCH BOX FORMING MACHINE

WS-8801: Left-Right and Right-Row Paper Lunch Box Forming Machine

WS-8802: Top-Down and Top-Row Paper Lunch Box Forming Machine

WS-8804: Clamshell-Shaped Paper Lunch Box Forming Machine

Classic 2-Compartment Lunch Box Forming Machine Since 1995

The WS- 8801 / 8802 / 8804 represents three decades of proven engineering excellence in two-compartment lunch box manufacturing, originally designed by Win Shine in 1995 and continuously refined to meet evolving market demands. This classic dual-section forming system delivers reliable 32 pieces per minute production with waterproof construction, supporting commercial food service operations that require consistent portion-controlled packaging. The 30-year heritage demonstrates enduring design relevance and operational reliability across global markets.

High-Speed Production Performance

Achieving 28-32 pieces per minute production speed, the WS-8801/8802/8804 delivers exceptional throughput for two-compartment configurations, enabling daily volumes exceeding 10,000 lunch boxes across standard production shifts. This high-speed capability supports large-scale catering operations, institutional food services, and commercial meal preparation facilities managing high-volume order fulfillment. The consistent production rate ensures predictable scheduling coordination between food preparation and packaging availability for time-sensitive meal services.

The reliable mechanical operation maintains steady output throughout extended production runs, minimizing downtime and maximizing operational efficiency. This performance consistency makes the WS-8801/8802/8804 ideal for operations dependent on uninterrupted packaging supply for daily meal distribution.

PLA/PE Coated Paper Sustainability

The WS-8801/8802/8804's compatibility with both PLA and PE-coated paper positions operators at the forefront of sustainable packaging innovation. After years of development, the machine now accommodates single-sided and double-sided coated paper with PLA (polylactic acid) or PE (polyethylene) formulations, providing flexibility for environmental strategy implementation.

PLA-Coated Paper Benefits:

PLA-coated paper delivers 100% bio-based, compostable packaging that meets EN13432 and ASTM D6400 standards for industrial composting. This plant-derived coating completely decomposes into carbon dioxide and water in composting environments, offering waterproof, oil-resistant, and heat-insulation properties without petroleum-based materials. PLA coatings comply with FDA and EU food contact regulations while eliminating peculiar odors and hazardous substances associated with conventional PE materials.

PE-Coated Paper Performance:

Traditional PE-coated paper (300-340 g/m²) provides proven moisture and grease barrier properties at economical costs for operations prioritizing budget efficiency. Double PE-sided coating delivers enhanced leak resistance for high-liquid-content foods and extended storage applications. Studies show that full recycling of PE-coated lunch boxes could reduce carbon emissions by 54%, supporting circular economy initiatives.

Innovative Hot Air Heater Sealing

The WS-8801/8802/8804 employs advanced hot air heater sealing technology that creates reliable, leak-resistant closures without high-frequency components. Hot air sealing applies controlled heat through circulating air streams, fusing packaging materials to form airtight, tamper-proof seals. This method ensures waterproof construction essential for liquid-containing foods and moisture-sensitive applications.

Hot air technology provides several advantages over contact heating methods. The non-contact heat transfer eliminates seal bar contamination and reduces cleaning requirements. Uniform heat distribution across sealing zones ensures consistent bond strength regardless of material thickness variations. The gentle heating process accommodates delicate PLA-coated substrates without degrading biopolymer properties or compromising compostability.

No Rubber Band Packaging Innovation

A distinctive WS-8801/8802 feature eliminates rubber band requirements during packaging operations, significantly reducing packaging time and manual labor actions. This innovation streamlines post-production handling, enabling faster packaging workflows and reducing consumable material costs. The self-sealing box design maintains secure closure during stacking, transportation, and handling without external binding materials.

This rubber-band-free system reduces packaging process steps by 30-40%, improving labor productivity and minimizing repetitive motion injuries associated with manual band application. The simplified packaging workflow supports automated stacking systems and reduces training requirements for packaging line operators.

Fixed Mold Design Reliability

The WS-8801/8802/8804 features proven fixed mold design optimized for two-compartment production efficiency. Unlike changeable mold systems requiring frequent adjustments, the fixed configuration ensures consistent dimensional accuracy and reduces setup complexity. This design philosophy prioritizes production stability over format flexibility, ideal for operations focused on standardized two-section lunch box manufacturing.

Fixed molds deliver superior longevity compared to interchangeable systems, reducing replacement frequency and maintenance costs. The simplified mechanical interface minimizes adjustment points where wear occurs, extending operational lifecycles and ensuring consistent quality output across millions of production cycles.

Dual Model Dimensional Flexibility

WS-8801 Configuration:

The WS-8801 produces boxes measuring 145-175mm length × 100-145mm width × 32-42mm height, suitable for compact meal portions and single-serving applications. This dimension range accommodates children's lunch portions, snack packaging, and portion-controlled institutional meals.

WS-8802 Configuration:

The WS-8802 accommodates larger dimensions of 145-190mm length × 145-160mm width × 32-42mm height, supporting generous adult portions and multi-component meal applications. The wider format provides ample space for protein-and-side combinations popular in commercial catering and takeout services.

Both configurations maintain the same production speed and sealing technology, enabling operators to select models matching specific market segment requirements.

Compact Energy-Efficient Operation

With approximately 6.5KW electrical consumption and 500 ℓ/min compressed air requirements, the WS-8801/8802/8804 delivers energy-efficient performance compared to high-frequency sealing systems. The 280×130×240cm machine dimensions provide compact installation footprints that conserve factory floor space. At 900kg machine weight, the WS-8801/8802 offers lighter construction than multi-mold systems while maintaining operational stability during high-speed production cycles.

The streamlined utility requirements enable straightforward integration into existing facilities without requiring specialized electrical infrastructure or high-capacity air compression systems.

Market Applications

School Meal Programs:

Educational institutions utilize two-compartment lunch boxes for nutritionally balanced meals with main dish and side separation. The WS-8801's compact dimensions suit children's portion requirements, while the waterproof construction prevents leakage in backpacks and lunchrooms.

Corporate Catering and Delivery:

Business catering services depend on efficient two-section packaging for office meal deliveries and employee dining programs. The high production speed supports morning preparation windows for midday delivery schedules across metropolitan service areas.

Takeout and Quick-Service Restaurants:

Fast-casual dining and quick-service establishments leverage two-compartment boxes for protein-and-side meal combinations, sauce separation, and multi-item orders. The rubber-band-free closure simplifies high-volume packaging during peak service periods.

Healthcare Food Service:

Hospital patient dining and assisted living facilities use portion-controlled two-section boxes for therapeutic diet management and allergen separation. The PLA-coating option supports healthcare sustainability initiatives and composting programs.

30-Year Evolution and Refinement

Since the original 1995 design, the WS-8801/8802 has undergone continuous improvement incorporating operator feedback, material advancements, and sustainability requirements. The integration of PLA-coated paper compatibility represents significant engineering adaptation responding to global environmental mandates and consumer preferences. This evolutionary approach ensures the classic platform remains relevant amid changing market dynamics while preserving the fundamental reliability that established its reputation.

Sustainable Packaging Leadership

The WS-8801/8802's dual PLA/PE compatibility positions operators to meet diverse sustainability requirements across market segments. PLA-coated lunch boxes offer complete compostability for environmentally-focused customers and regulatory compliance markets. PE-coated options provide economical alternatives with established recycling infrastructure for cost-sensitive applications. This material versatility enables strategic substrate selection matching specific customer sustainability commitments and budget parameters.

Taiwan Manufacturing Heritage

Backed by Taiwan's precision engineering reputation and Win Shine's 30+ years of paper forming equipment expertise, the WS-8801/8802 represents proven long-term reliability. The three-decade production history demonstrates enduring mechanical design and field-proven performance across diverse operating environments. Quality manufacturing standards ensure consistent forming accuracy, waterproof sealing integrity, and operational longevity throughout extended service lives.

Customization and Technical Support

Win Shine provides comprehensive technical support including operator training, preventive maintenance programs, and spare parts supply for the WS-8801/8802 platform. Custom dimension specifications and compartment configurations can be developed for specialized application requirements. Material compatibility testing assists operators transitioning to PLA-coated substrates, ensuring optimal sealing parameters for new formulations.

Request Equipment Information

Contact Win Shine Machinery for detailed specifications, production samples, PLA/PE material testing, and facility integration consultations. Engineering teams provide compartment layout optimization, sustainability material analysis, and production capacity assessments supporting equipment investment decisions. Request demonstrations and trial runs evaluating the WS-8801/8802 Classic for specific two-compartment lunch box manufacturing requirements.