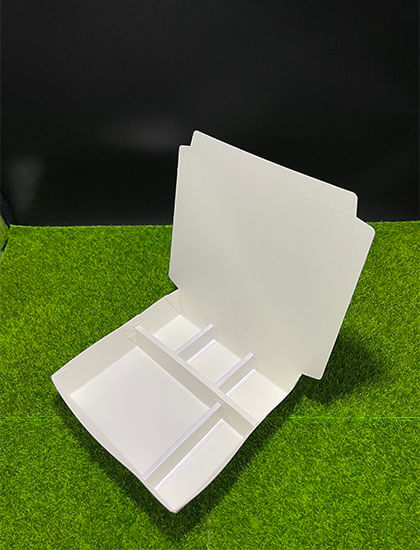

WS-8809MA High Speed Paper Compartment Lunch Box Machine

Product Introduction

Specification

| Model | Dimension | ||

| L | W | H | |

| WS-8809MA | 145-175 | 100-145 | 32-38 |

|---|---|---|---|

| No. | WS-8809MA |

| Description | |

| Production Speed (pcs/min) | 35 |

|---|---|

| Paper Material | Single or Double PE |

| Sealing Method | Heater + Hifrequency |

| Electrical Requirement | 8KW |

| Compressed Air | 6kg, 20Liter/min |

| Machine Dimension (LxWxH cm) | 420 x 320 x 220 |

| Machine Weight (NW kgs) | 4800 |

* Customized design in welcome.

* We reserve the right to alter specifications without prior notice.

Advantage:

- This is A Lowest Power Consumption Machine.

- This is A Highest Speed Machine In the World.

- To make your money back more quickly

- Decrease 116,000kw/year

- Two sets by one operator

- Production Speed: 36 pcs/min

- Machine Dimension: 360(L) x 270 (W) x 225 (H) cm

High-Speed 3-5 Compartment Lunch Box Forming Machine

The WS-8809MA/8809B/8809ER series delivers industrial-grade production capacity for 3-5 compartment paper lunch boxes, combining advanced sealing technology with energy-efficient operation for high-volume food packaging manufacturers. This automated forming system integrates heater and high-frequency sealing methods to ensure leak-resistant closures while maintaining consistent output quality at speeds up to 35 pieces per minute.

Advanced Dual Sealing Technology

The WS-8809MA employs a sophisticated heater plus high-frequency sealing combination that delivers superior cover closure strength compared to single-method systems. This dual-technology approach ensures reliable leak resistance for liquid-containing foods and maintains structural integrity during transportation and handling. The high-frequency sealing component creates molecular-level bonding between PE-coated paper layers, while the heater element provides uniform temperature distribution for consistent seal quality across all production units.

Versatile Paper Material Compatibility

Supporting both single and double PE-coated paper materials, the WS-8809MA series offers flexibility for manufacturers working with different substrate specifications. Single PE coating provides cost-effective solutions for dry food applications, while double PE construction delivers enhanced moisture barrier properties for high-liquid-content meals. This material versatility enables production adaptation to diverse menu requirements without equipment changeover.

Technical Specifications

Production Capabilities:

The WS-8809MA model achieves consistent output at 35 pieces per minute, supporting daily production volumes suitable for industrial catering operations, institutional food services, and commercial packaging facilities. The forming range accommodates box dimensions from 145-175mm length, 100-145mm width, and 32-38mm height, covering standard portion sizes for multi-course meals and compartmentalized takeout applications.

Power and Utilities:

With an 8KW electrical requirement and 6kg compressed air consumption at 20 liters per minute, the WS-8809MA maintains energy-efficient operation while delivering industrial production capacity. The compact footprint of 420×320×220cm (L×W×H) optimizes factory floor utilization, while the 4,800kg machine weight ensures operational stability during high-speed forming cycles.

3-5 Compartment Configuration Flexibility

The series accommodates multiple compartment layouts from 3 to 5 sections, enabling manufacturers to produce portion-controlled packaging for diverse meal types. Three-compartment designs suit balanced meal presentations with main dish, side, and accompaniment separation. Four-compartment configurations support elaborate menu offerings with multiple side dishes, while five-section layouts provide premium meal packaging for comprehensive food service applications.

Applications Across Food Service Industries

Commercial Catering and Delivery:

High-volume catering operations and food delivery services utilize the WS-8809MA series to produce standardized compartment boxes that maintain food separation during bulk meal preparation and distribution. The consistent forming quality ensures professional presentation while the leak-resistant sealing protects food quality during transport.

Institutional Food Programs:

Schools, hospitals, corporate cafeterias, and institutional dining facilities implement this equipment to manufacture portion-controlled lunch boxes that meet nutritional guidelines and dietary requirements. The compartmentalized design supports balanced meal planning and visual portion management.

Takeout and Quick-Service Restaurants:

Fast-casual dining establishments and quick-service restaurants depend on the WS-8809MA series for consistent packaging production that accommodates multiple menu items in single containers. The compartment separation prevents flavor mixing while maintaining compact packaging dimensions.

Customization and Engineering Support

Win Shine provides comprehensive customization services for specialized production requirements beyond standard configurations. Engineering teams collaborate with customers to develop custom mold designs for unique compartment layouts, specific dimensional requirements, and specialized sealing parameters. Technical support encompasses mold development, production testing, operator training, and ongoing maintenance assistance to ensure optimal machine performance throughout operational lifecycles.

Sustainable Packaging Production

Paper lunch box manufacturing aligns with global initiatives to reduce plastic food packaging waste and transition to biodegradable alternatives. The WS-8809MA series supports eco-friendly production strategies by processing recyclable PE-coated paper materials that decompose significantly faster than plastic containers. This sustainability positioning helps food service businesses meet environmental compliance requirements while satisfying consumer preferences for responsible packaging.

Quality Assurance and Taiwan Manufacturing

Backed by Taiwan's precision manufacturing reputation and Win Shine's decades of paper forming equipment expertise, the WS-8809MA/8809B/8809ER series delivers reliable production output with minimal downtime. Quality control protocols ensure consistent forming accuracy, sealing integrity, and dimensional tolerances across extended production runs. The robust construction and proven component reliability reduce maintenance requirements and extend equipment service life.

Request Product Information

Contact Win Shine Machinery for detailed specifications, production samples, custom configuration consultations, and facility planning support. Request equipment demonstrations, ROI assessments, and technical documentation to evaluate the WS-8809MA series for specific production requirements. Engineering teams provide site assessments and production workflow analysis to optimize equipment integration with existing packaging operations.