Product Selection Guide

Win Shine Machinery has dedicated ourselves to developing high-quality paper food container making machines to meet the needs of our customers.

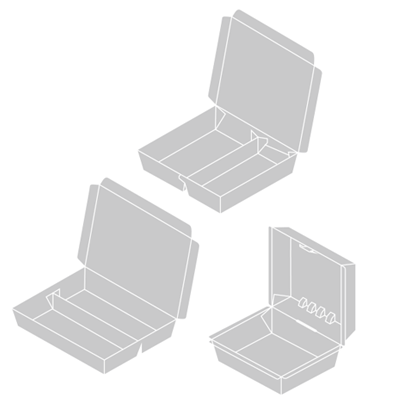

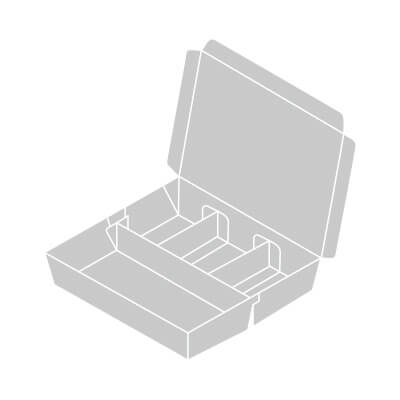

Main Products:Variety of 1~5 Compartment paper lunch box forming machine,Carton Erecting Machine for Hamburger Box, Paper box for French Fries or cakes, Paper tray and Food pail Box,Food Pail Forming Machine, Paper Pail Forming Machine, Food Container Forming Machine, Paper Pail, Fold-Pak, Takeout Box, Takeout Containers,Disposable Paper Take Out Food Containers,Automatic Paper Cup Machine / Paper Plate and Bowl Making Machine.

For the production of paper cups, paper trays, and paper lunch boxes, we provide the purchase guide of environmentally friendly professional paper lunch box forming machines.

The global paper lunch box machine market is experiencing a dynamic shift, propelled by the increasing demand for eco-friendly packaging solutions. The market is segmented by product type, application, capacity, material, and technology, with significant contributions from key players such as Newlong Industries, Ltd., and DS Smith Packaging Limited. The trend towards sustainable practices in the food industry, driven by rising environmental concerns, is fostering growth in this sector. Innovations in technology, such as single and double mould machines, are enhancing production capabilities, catering to various applications from food industry to supermarkets and schools. The market is also influenced by factors like the capacity of machines, ranging from low to high, and the use of materials like corrugated paper, kraft paper, and coated paper, which are pivotal in determining the efficiency and sustainability of the end product.

The Asia Pacific region is projected to witness profitable growth due to its dynamic economic landscape and burgeoning demand for efficient packaging solutions. Countries like China and India are leading the way, with their rapid industrialization and evolving consumer lifestyles contributing significantly to the growth of the food and beverage industry. This, in turn, is driving the demand for automated and sustainable packaging processes. Fully automatic paper lunch box machines, which are indispensable for the quick and effective production of eco-friendly paper lunch boxes, are meeting the growing need for convenient and sustainable packaging solutions that align with the region's increasing sustainability consciousness.

Moreover, the market is navigating through challenges such as the technical complexity associated with fully automatic paper lunch box machines, which combine advanced automation systems, complex sensors, and precision control devices. These complexities present hurdles in understanding, operating, and maintaining the machines, necessitating specialized training for operators and technicians. However, the cost-effectiveness of these machines is a key driving factor, as they automate various production stages, eliminate the need for manual labor, reduce human error, and produce large quantities of lunch boxes in a short time, thereby enhancing output and reducing delivery times.

The competitive landscape is intense, with the growing demand for sustainable packaging solutions leading to an influx of manufacturers and heightened competition among existing players. The introduction of innovative products and aggressive marketing strategies by new entrants or existing competitors could lead to shifts in market share, directly impacting revenue and long-term business sustainability. The COVID-19 pandemic also had a significant impact on the market, with disruptions in international supply chains and manufacturing operations slowing down production during the early stages of the pandemic. Restrictions on labor mobility and transportation reduced the supply of raw materials, affecting manufacturers' production capacities. Health and safety concerns led to an increased demand for packaged foods and takeaways, thereby driving the need for efficient automated packaging solutions like fully automatic paper lunch box machines.

In conclusion, the global paper lunch box machine market is a complex ecosystem influenced by a myriad of factors, from technological advancements and material choices to economic shifts and consumer trends. As the industry moves forward, it will continue to evolve, shaped by the continuous push for sustainability and efficiency in packaging solutions.

| MODEL | WS-1101MA WS-1100 WS-1105C | WS-1107 | WS-8801 WS-8802 WS-8804 | WS-8809MA WS-8809ER | WS-8809B | WS-8809HC WS-8809HR | WS-9905 WS-9905D | WS-3300N WS-3301 WS-3302 | WS-3303 | |

|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

||

| Water Proof | ● | ● | ● | ● | ● | ● | ● | ● | ||

| Grease Proof | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| Bio Paper/Plastic free | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| PE coating Paper | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| Corrugated Paper | ● | |||||||||

| PP coating paper | ●★ | ●★ | ● | ● | ● | |||||

| PLA coating paper | ● | ●★ | ●★ | ●★ | ●★ | ●★ | ● | ● | ● | |

| Heat Resistant Paper | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| Mold change | ● | ● | ● | |||||||

| Sealed by Glue | ● | |||||||||

| Sealed by heating | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

The paper lunch box machine market is increasingly focusing on sustainability and eco-friendly materials to address environmental concerns and meet consumer demands for greener products. Here are the key aspects of this trend:

-

Use of Eco-friendly Materials

-

Sustainable Paper Sources:

Manufacturers are sourcing paper from sustainably managed forests certified by organizations like the Forest Stewardship Council (FSC). This ensures that the raw materials are renewable and responsibly harvested.

-

Biodegradable and Compostable Materials:

There is a growing use of biodegradable and compostable materials for making paper lunch boxes. These materials break down more easily in the environment, reducing the impact of waste and promoting a circular economy.

-

-

Eco-friendly Production Processes

-

Reduction of Carbon Footprint:

Modern paper lunch box machines are designed to minimize energy consumption and reduce carbon emissions during the manufacturing process. Energy-efficient machines help lower the overall environmental impact.

-

Waste Minimization:

Automated machines are programmed to optimize the cutting and forming processes, ensuring minimal material wastage. This not only conserves resources but also reduces the amount of scrap paper generated during production.

-

-

Innovation in Machine Design

-

Advanced Technologies:

Machines incorporating IoT and AI technologies enable precise control over production processes, leading to more efficient use of materials and energy. These technologies also facilitate real-time monitoring and predictive maintenance, further enhancing sustainability.

-

Customization Capabilities:

The ability to produce various shapes and sizes of lunch boxes with the same machine reduces the need for multiple machines, saving resources and energy. Customization also caters to specific consumer needs, promoting the use of sustainable packaging.

-

-

Regulatory Compliance and Certifications

-

Adherence to Environmental Standards:

Companies are increasingly aligning their production processes with environmental regulations and standards. Compliance with these standards ensures that the manufacturing of paper lunch boxes is eco-friendly and sustainable.

-

Certifications:

Products certified as eco-friendly by recognized bodies (e.g., FSC, PEFC) gain consumer trust and meet market demand for sustainable products. These certifications play a crucial role in promoting environmentally responsible manufacturing practices.

-

-

Market Trends and Consumer Demand

-

Shift towards Green Packaging:

There is a significant shift in consumer preference towards green packaging solutions. This trend is driving the demand for paper lunch boxes made from eco-friendly materials and manufactured through sustainable processes.

-

Government and Corporate Initiatives:

Various government policies and corporate sustainability goals are encouraging the adoption of eco-friendly packaging. Companies are investing in sustainable technologies to meet these goals and remain competitive in the market.

-

In summary, the paper lunch box machine market is heavily focused on sustainability through the use of eco-friendly materials, innovative machine designs, and adherence to environmental standards. These efforts are crucial in reducing the environmental impact of packaging and meeting the growing demand for sustainable products.